Tablet presses are "star equipment" in industries such as pharmaceuticals, food, health products, and chemicals. Whether it is a small tablet or a piece of chewing gum, the efficient compression of a tablet press is indispensable behind the scenes. Many enterprises encounter a common problem when using tablet presses: as the equipment runs for a long time, issues such as loud noise, unstable tablet compression, and rapid die wear occur. Ultimately, this is often due to inadequate lubrication.

What are the common types of tablet presses?

Single-punch tablet presses: Often used in research and development as well as small-batch trial production;

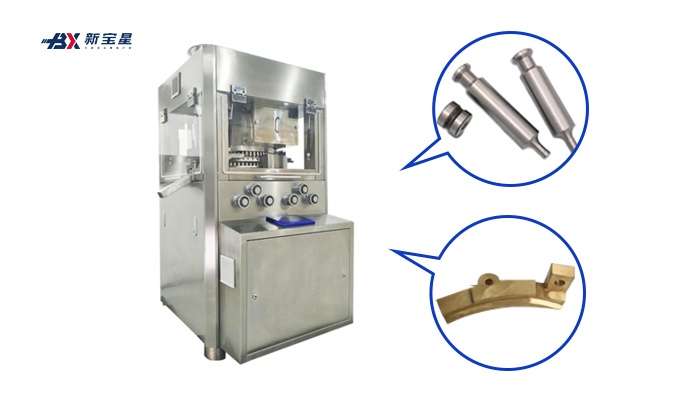

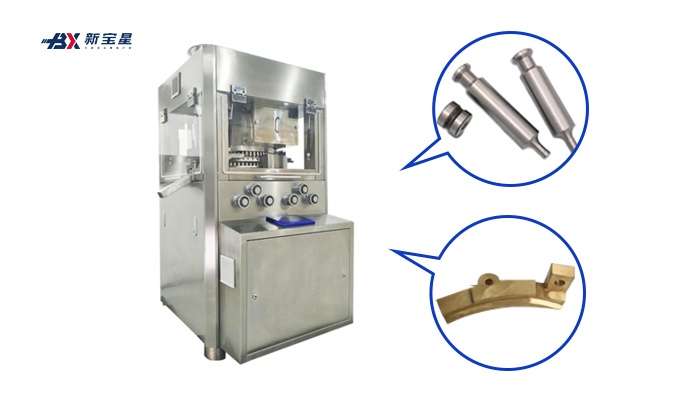

Rotary tablet presses: High production capacity, widely used in pharmaceutical factories and food factories;

High-speed tablet presses: High degree of automation, serving as the main equipment in large pharmaceutical enterprises.

Although different types of tablet presses vary in structure, they all share a common requirement—all structural components must be properly lubricated.

Key Structures and Lubrication Pain Points of Tablet Presses

Main drive system: It bears long-term high-load operation. Ordinary grease is prone to heating and oxidation, leading to increased gear wear.

Turntable and punch die: Directly in contact with materials. Inadequate lubrication will cause die wear, uneven tablet compression, and even powder falling. Food-grade or pharmaceutical-grade grease must be used to avoid tablet contamination.

Pressure rollers and guide rails: High-strength extrusion parts that bear impact loads. If the lubricating film is not strong enough, scratches and debris are likely to occur, affecting tablet quality.

Feeding mechanism: Requires low friction and no material jamming. However, the environment is often dusty, which easily causes lubricating grease to mix with dust and affects fluidity.

Seals: Common rubber or plastic rings. Improper oil selection can easily cause swelling or hardening, leading to oil leakage and powder leakage.

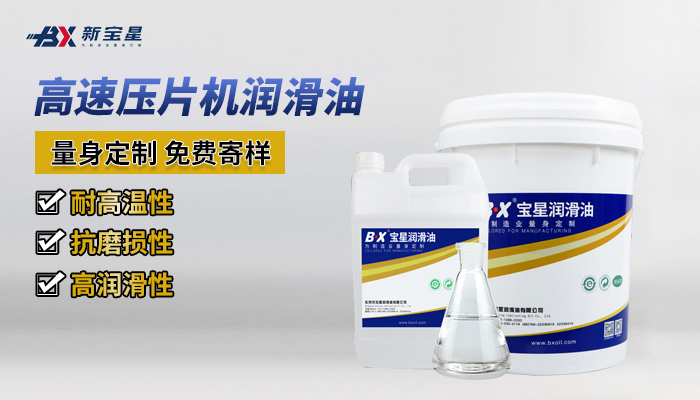

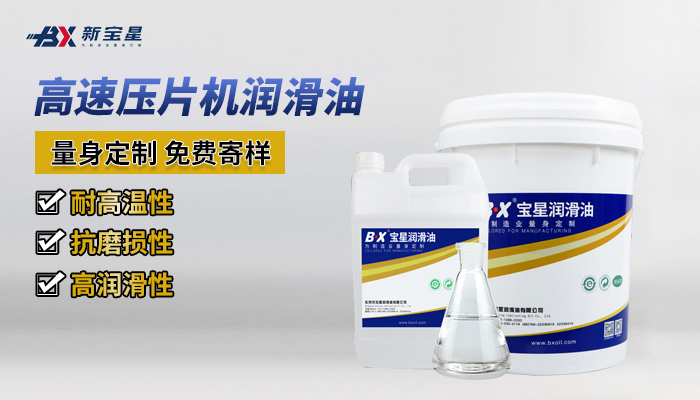

To meet the complex needs of tablet presses, Baoxing food-grade lubricating grease, food-grade lubricating oil, and food-grade lubricating spray have high anti-wear and high-load performance; comply with NSF H1 food-grade certification, ensuring safety and no pollution; possess excellent waterproof, mildew-proof, and rust-proof properties; and are compatible with metals, plastics, and rubber. Whether in the pharmaceutical, food, or cosmetics industry, Baoxing can provide professional and suitable lubrication solutions for tablet presses.