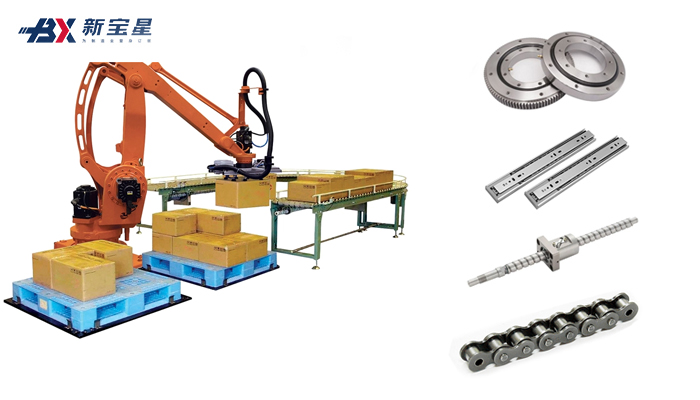

As an efficient handling equipment in logistics, warehousing and other fields, palletizing robots operate in high-frequency and heavy-load environments all year round. The stability of the lubrication system directly affects their productivity and service life. To make the equipment "strike less", we must first sort out the core oil points and common pain points.

Core oil points of palletizing robots

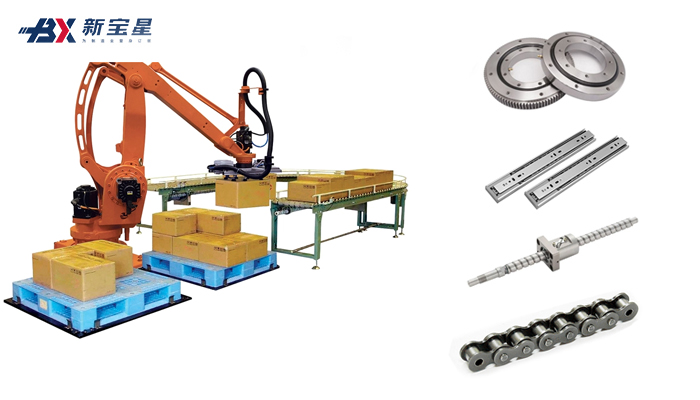

Heavy-load joints and gearboxes: As key parts for carrying heavy objects, they need to bear the impact load caused by frequent start-stop. High extreme pressure lubricating grease, such as lithium-based or polyurea-based lubricating grease, should be selected. Its strong oil film strength can effectively resist metal friction under heavy loads.

Guide rails and sliders: Responsible for precise positioning and smooth sliding, lubricating grease with a low friction coefficient should be selected, which can not only reduce movement resistance, lower energy consumption, but also reduce the wear of seals and extend their service life.

During high-speed operation of the equipment, centrifugal force can easily throw ordinary lubricating grease off the surface of gears or joints, resulting in "oil shortage" in lubricated parts, which not only aggravates wear but also requires manual regular grease replenishment, increasing extra workload.

Under high-load working conditions, ordinary lubricating grease has insufficient oxidation resistance and shear resistance, and its service life is greatly shortened. Frequent grease replacement not only consumes costs, but also shutdown maintenance will directly affect the production progress.

High-frequency friction during gear meshing is prone to produce harsh noise, and long-term vibration will also affect the positioning accuracy of the equipment, causing potential impact on the working environment and product quality.

Baoxing BX-800 series robot-specific lubricating grease can also provide precise lubrication support for palletizing robots: its high extreme pressure performance is suitable for heavy-load joints, low friction characteristics are suitable for guide rails and sliders, and strong adhesion and noise reduction design specifically solve the pain points such as grease loss and noise, helping the equipment operate efficiently.

Want to make palletizing robots get rid of lubrication troubles? Welcome to call for consultation and get free samples to experience the adapted solution!