In cable equipment, when many people mention the use of grease, their first reaction is "anti-wear" or "smoother assembly". However, under actual operating conditions, what the grease for cable equipment really needs to solve is the problem of conductive stability and resistance control.

Cable joints, terminals, connectors, and current-collecting parts are often affected by vibration, thermal expansion and contraction, current impact, etc. during long-term energized operation. Even if the contact is good at the initial stage of assembly, after running for a period of time, the contact may degrade from "surface contact" to "point contact" due to small changes in gaps, and the contact resistance will increase accordingly.

Once the contact resistance increases, the problem is not just "heating". It may also cause local overheating, increased energy loss, and even the risk of arcing and ablation, becoming a hidden danger of equipment failure.

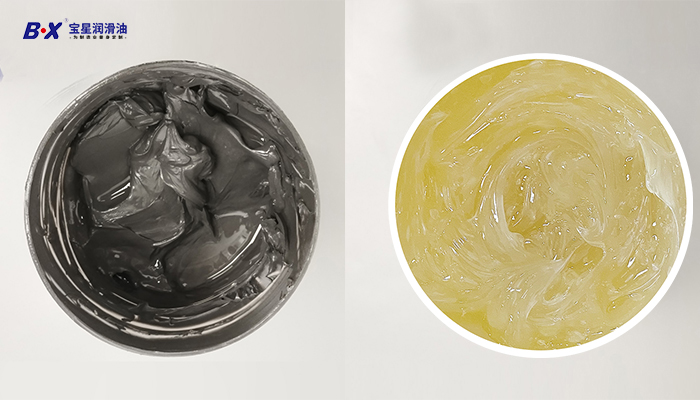

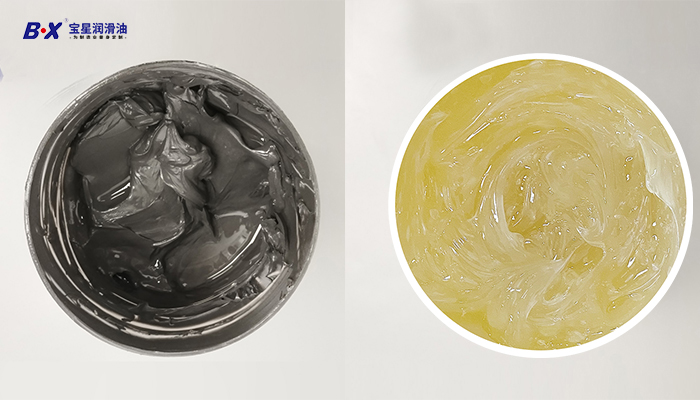

The primary function of conductive grease is filling. It can fill the micro-gaps between metal contact surfaces, making the originally discontinuous contact interface form a stable conduction path, converting point contact into more uniform surface contact, and fundamentally improving conductive continuity.

Second, it enhances conductivity and reduces contact resistance. Through the uniform distribution of conductive media, the current transmission is more stable, reducing resistance fluctuations and lowering temperature rise and energy consumption caused by excessive resistance.

Third, it has high-temperature stability. When cable equipment operates at high current or in a high ambient temperature, the grease must maintain structural stability at high temperatures, without loss, coking, or damaging the conductive path. Otherwise, it will instead aggravate the problem of poor contact.

Therefore, when selecting grease for cable equipment, we should not only focus on "whether it is conductive", but also pay attention to its filling capacity, conductive stability, high-temperature resistance, and reliability during long-term operation.